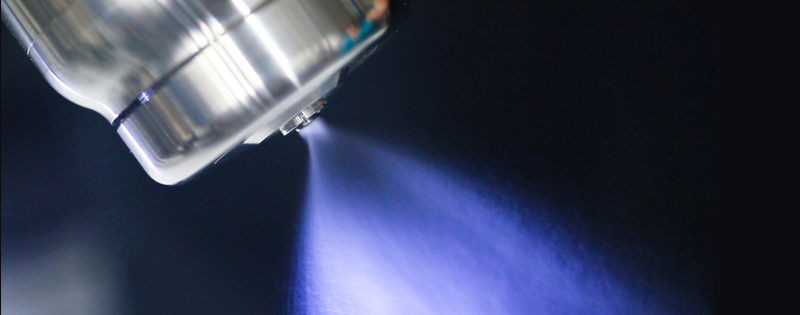

Nylon 11 Coatings

Nylon coatings are thermoplastic polyamide powder coatings typically applied to metals electrostatically or in a fluid bed. This substance protects metal substrates like aluminum and steel, combating corrosion, abrasion, and impact-related damage. These renewable raw materials are also free of heavy pigments. Many companies choose nylon 11 powder coatings because they contribute a glossy, even finish to metal components, making these parts more visually appealing.

With over 45 years of experience coating and pretreating industrial and military components, Advanced Coating Technologies is the nylon 11 powder coating company you can trust. We use our highly skilled operators and efficient automation technologies to perform nylon coating services with the utmost quality and productivity.

Nylon 11 Coating Applications

Nylon 11 powder coatings are highly versatile for use across many major industries. Companies use this substance to coat parts, components and machines in numerous fields, such as:

- Medical: Due to their hygienic properties, nylon coatings are often applied to medical devices like catheters, defibrillator paddles, tubing hubs and forceps.

- Oil and gas: These powder coatings are applicable for oil and gas components like umbilicals and underwater pipes.

- Information technology (IT): You can use this film on IT products like semiconductors, wires and cables.

- Rollers: Nylon 11 is suitable for various types of rollers, including conveyor rollers, print rollers and pulleys.

- Automotive: Many automotive parts benefit from nylon coatings, such as quick connectors, pneumatic brake lines, and monowall and multilayer fuel lines.

- Wire products: You can apply nylon 11 powder coatings to household items like shelving and dishwasher racks.

- Water management: Because nylon coatings have low moisture absorption properties, they're useful for water management components like impellers, piping systems, pump housings and water reticulation equipment.

Anti-Corrosive Properties of Nylon 11

Nylon 11 is best known for its corrosion-resistant properties, making it highly durable against tarnishing and abrasion. This thermally stable powder coating also offers multifunctional protection with numerous additional benefits, including:

- Chemical defense: Nylon coatings protect metals against chemical contamination, including ozone, salt spray, solvents, ultraviolet (UV) rays and hydrocarbons.

- Impact resistance: According to Charpy impact tests, nylon coatings demonstrate exceptional resistance at both low and room temperatures, meaning they can absorb impact energy without breaking.

- Prolonged life cycle: Nylon coatings for metal are weather-resistant, giving them a long-lasting service life.

- Hygienic surface: This coating is widely used for drinking water applications due to its hygienic properties.

- Abrasion resistance: Due to their high abrasion resistance, nylon coatings project a smooth and even surface finish.

- Mechanical durability: Nylon 11 is mechanically tough, with high burst strength across an extensive temperature range.

Trust a Reliable Nylon 11 Powder Coating Company for Nylon Coating Services Today

You can protect your metal surfaces with nylon coating services from Advanced Coating Technologies. We've provided our customers with high-quality, expertly applied coatings since our establishment in 1976, using modern coating equipment to optimize our powder and liquid paint coating capabilities. Our highly skilled operators are experienced in coating numerous components, including cast, machined, welded, forged and stamped parts for various industries and applications.

Fill out a form to request a quote for your next project, or contact us with any questions you may have about our services today!