Powder coating is a tried and true method of finishing materials such as glass, plastics, fiberboard and metals. Compared to paint, powder coating has several unique advantages, such as a more even coating, increased durability and better sustainability. At Advanced Coating Technology, we've perfected the powder coating process and are ready to provide you with the intense durability and longevity that comes with a powder coated finish.

While powder coat and paint are very similar, they both excel at finishing different products due to their unique compositions. Paint is a more affordable solution that is easier to color match, but it also contains solvents that make it hazardous to store and can harm the environment. Comparatively, powder coatings provide better coverage, more wear resistance, lower maintenance requirements and better environmental sustainability than paints. While powder coats may cost you more upfront, their highly durable nature means you'll pay less for them over time.

Powder coating comes in a range of textures, finishes, thicknesses and colors to complement virtually any workpiece. It can be customized to achieve textures that are glossy, matte, clear, metallic or glittered. Powdered coatings are perfect for creating layers both thick and thin and can be greatly customized to fit your projects.

As these finishes are highly resistant to heat and corrosion, they contribute to producing some of the most durable parts on the market. For instance, powder coating on stainless steel — an inherently durable material prized for similar characteristics — yields components that can resist even the harshest environments.

Much like painting, powder coating requires a thorough preparation of all components in order to ensure the coating adheres properly. The preparation stage begins with a thorough cleaning of the substrate to ensure it is free of contaminants. This preparation may also include mechanical cleaning that uses blasting or abrasion to completely remove any leftover old finishes or stubborn contaminants — this step is an essential part of the powder coating process for stainless steel, as the surface of the steel must be roughened to promote adhesion.

Substances such as solvents, grease, oil and residue may be removed with neutral detergents or weak alkali.

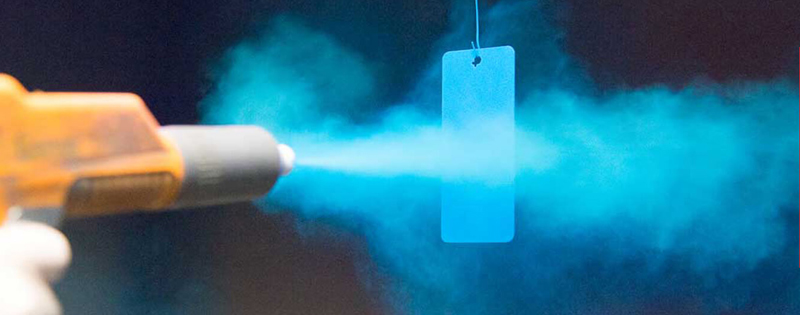

There are two distinct methods of applying powder coats — electrostatic deposition and fluidized bed powder coating. The type of application used is determined by the unique demands of the components being coated, with the substrate's heat tolerance usually being the determining factor.

In an electrostatic deposition, the coating is applied using an electrostatic spray deposition in a powder spray booth. The fluidized powder material is then distributed from a feeder to a spray gun that imparts the powder with an electric charge. This charge allows the powder to completely adhere to the substrate and stay there as long as the charge remains. The remaining overspray can be collected in a recovery system. Once the layer of powder is in place, the components are sent to be cured.

The fluidized bed powder coating method works by preheating parts and dipping them into powdered material inside a fluidized bed. This method is used on substrates that can withstand high temperatures and helps eliminate the need for overspray recovery systems. Overall, both methods yield excellent total coverage and an equally effective powder coat.

The curing process differs between electrostatic deposition and fluidized bed powder coating methods. For electrostatic deposition, parts are cured in a powder curing oven that is typically operated at between 325 and 450 degrees Fahrenheit. Depending on the size and shape of the parts, the cure time will range anywhere from 10 minutes to an hour. During the curing process, powder particles begin to melt and form a continuous coating over the part's surface.

To cure fluidized bed coated parts, the parts can be coated before or after being passed through the powder coating cloud. In the first method, the parts do not require additional curing, and in the second method, the part is cured in an oven similar to that used during the electrostatic deposition process.

The experts at Advanced Coating Technology have extensive experience performing the powder coating process and are ready to find you the perfect coating solution for your business. We've spent more than 40 years perfecting our powder coating methods and have the expertise necessary to apply these finishes to everything from food production equipment to medical equipment and furniture. We also provide durable corrosion- and heat-resistant powder coating solutions.

To learn more about our powder coating process and what we can apply it to, contact us online or request a quote.