The durability of powder coating is well-known throughout industries that use it, from automotive to aerospace. This hard-wearing finish can last for more than a decade when applied correctly and used in a suitable environment. Discover more about how long powder coating should last and the variety available for different applications.

Powder coating is a finish that uses dry powder applied to a pretreated surface. To apply the powder, the dry particles have a static charge, which makes them adhere to the grounded metal surface of the item getting the coating. This process creates an even finish that does not require solvents for application and can last for years.

A powder coating finish of 15-20 years is possible. Note that this type of longevity depends on several factors.

How long powder coating lasts depends on the type of coating you choose and where you use it. So, you should be more specific when asking about this finish's longevity. To get a more accurate answer, ask instead, "How long will powder coating last outside?" or, "How long does powder coating last on wrought iron?" Those condition specifics can get you an answer for your particular application, which can still fall in the 15-20 years range.

Several factors play into the longevity of this type of finish, including:

Powder coating provides industries with the benefit of a long-lasting, durable finish. In fact, several industries as varied as chemical processing and computer manufacturers use this type of finish.

The biggest advantage of powder coating is its resistance to wear. Depending on the finish, it could hold up to UV ray exposure, moisture or heat. Plus, some types offer friction reduction on surfaces, allowing for a dry lubricant option.

Longevity is another advantage of this finish. With lifespans up to 20 years, it is an investment in a product designed to hold long into the future.

The powder coating finish serves the needs of multiple industries. Within these sectors, the applications of the coating can overlap with other groups. For instance, engine parts in both ground transportation and aerospace industries may use powder coating for durability and dry lubrication. Some of the common uses of this finish include those in the following industries:

The powder coating treatment process takes less time than painting. The length of time depends on the type of cleaning used, whether you have a primer coat and additional considerations. Unlike painting, which often requires multiple topcoats, powder coating only needs one.

Pretreatment is critical for getting the coating to stay and evenly coat the metal surface. The process of pretreating the metal removes anything from the surface that could prevent the electrostatically charged powdered coating from sticking. Things removed during this pretreatment process include grease from production, dust or shavings, previous coatings, oils or other surface contaminants.

The pretreatment process involves a few steps to prep items for the finishing process, including:

Preparing the surface to ensure its cleanliness and readiness to accept the powder coating will allow the coating to last longer. This stage might also involve standing items on racks or fixtures to support them during the coating process.

Finish lifespans depend on how much pretreatment the surface receives. If you skip pretreatment or cleaning the surface, the finish will have a dramatically reduced life and not be as durable. If you want exceptional performance and longevity, demand high-quality, thorough pretreatment before the coating process.

Pretreating the surface before applying a powder coat or before painting follow similar steps. Both processes require cleaning the surfaces thoroughly. However, most painting jobs will require the application of a base coat or primer before the main painting process starts. This base must dry completely before adding any other layers of paint on top. Powder coating typically does not require a base coat. But the surface preparation by cleaning and the removal of grime ensures success for both types of finishes.

Powder coating's appeal lies in its durability and longevity. Depending on the specific finish you choose, you could enjoy moisture resistance, UV protection, chemical resistance and impact damage reduction. Finishes have designations for indoor or outdoor use. Follow these recommendations carefully because if used improperly, the finish will not perform as expected.

The environment the finish has exposure to during use determines its longevity. For example, epoxy coatings can fade in direct sunlight. Therefore, only choose these types of finishes for use on indoor appliances or other metals used exclusively inside.

On the other end of the spectrum are ceramic metallic (cermet) coatings. These can readily withstand the harshest conditions, including protecting against corrosion and temperatures up to 1,200 degrees Fahrenheit. This type of coating works well in outdoor environments that need a high-performance coating, such as exhaust equipment used for automobiles and other vehicles.

The durability and longevity of powder coatings are important factors. Due to its ability to last for years without maintenance, it provides a more cost-effective finish compared to paints. Painted surfaces need regular touchups to continue to maintain their color and quality. Powder-coated surfaces do not need this level of care.

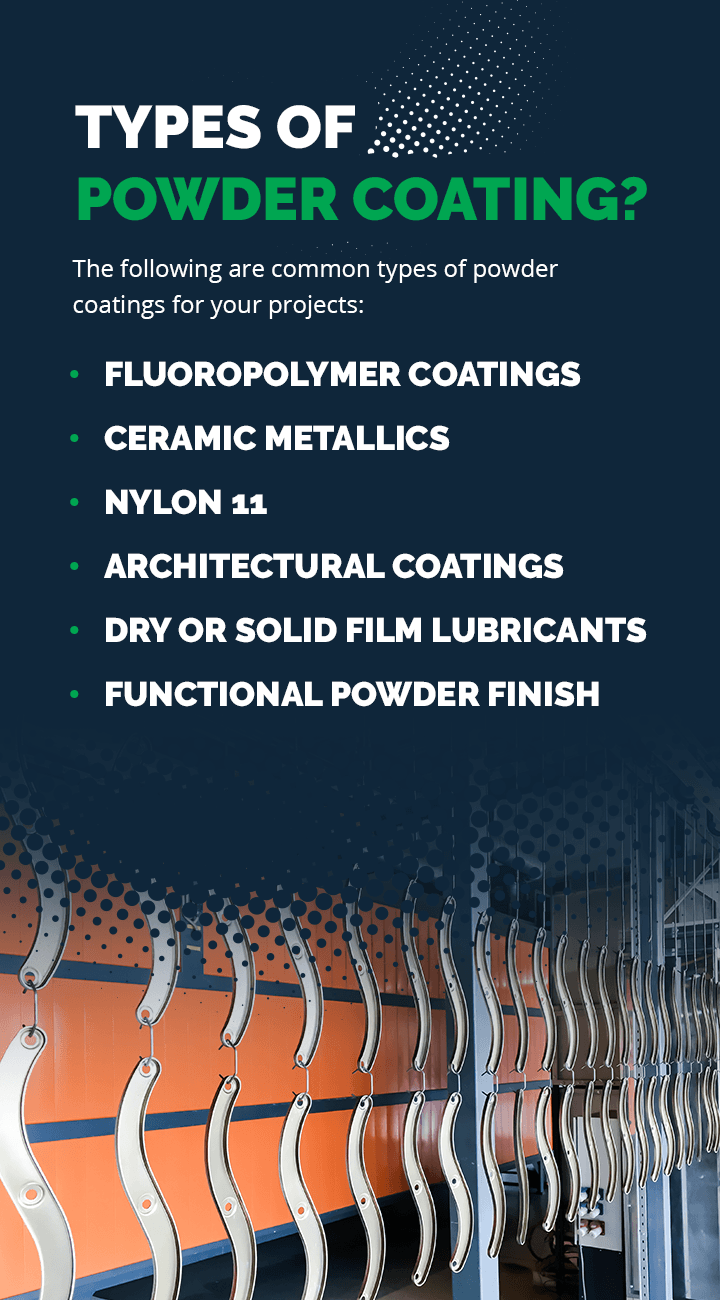

The type of finish you choose will affect its performance in certain environments and its longevity. To get the most durable coating, choose an option designated for outdoor use. You may also want to balance the cost-effectiveness of the finish with performance. In such cases, decide if an indoor-only finish, such as an epoxy, will offer the performance you need. The following are common types of powder coatings for your projects:

Fluoropolymer coatings include Dykor® and Xylan® coatings. Within each of these brands are different types of coatings for specific applications. All types of coatings within this category perform exceptionally well in resisting corrosion and chemical damage. Additionally, these finishes provide nonstick, low friction properties while performing at temperatures up to 550 degrees Fahrenheit. Consider the qualities of these coatings to determine which could work for you:

The nonstick properties, heat resistance and durability make fluoropolymer coatings the first choice for food molds, car parts, threaded fasteners, sliding surfaces, architectural components, vacuum molds and thermo-form molds.

Cermet coatings have the highest performance at extreme temperatures, up to 1,200 degrees Fahrenheit. Consequently, these coatings work exceptionally well for truck and motorcycle exhausts and in the following industries:

Additionally, options for cermet can allow for flexibility of the surface or electricity conduction. This unique composite finish combines the properties of metals and ceramics to create its distinctive set of high-performance properties.

Nylon 11 polymer coating offers wear resistance, noise reduction, machinability, warm surface feel and dry lubrication. Due to the thickness of this surface coating, some processes may require applying nylon coating all over and removing some of the coatings from sections of a piece.

Metal parts that need wear resistance and lubrication while maintaining their machinability can use nylon 11 as their coatings.

Various coatings in the architectural industry require resistance to outdoor conditions. Resistance to weathering sets architectural coatings apart from other types. Within this category are polyester and Super Durable Polyesters. These polyesters designated for outdoor use include triglycidyl isocyanurate crosslinkers (TGIC) and TGIC-free options.

TGIC helps the curing process while providing weather protection. Finishes that don't use TGIC and offer weather resistance are also popular in some areas due to local preferences. The differences between TGIC and TGIC-free polyester finishes come down to the specific needs for a project.

Powder coatings can create dry or solid film lubricants on surfaces. These types of finishes allow for smooth movement between surfaces. For instance, nylon 11 and cermet finishes can help surfaces avoid sticking to each other. These finishes reduce the need for liquid lubricants that can wear off or build up, requiring regular cleaning and reapplication. Moving parts that need a smooth operation can benefit from these types of finishes.

Functional powder finishes include a variety of applications that offer performance but don't focus on appearance. For example, you can choose epoxy coatings for electrical insulation. In this application, you can get up to 1,000 volts of dielectric strength per mil. While the epoxy coating does not offer outdoor weather protection, it performs exceptionally well as an indoor-only insulator.

Another functional use of this coating is as a primer. A zinc-rich primer can enhance the corrosion resistance of coating over it.

By choosing powder coating for metal surfaces, you gain a finish that can last up to 20 years and stand up to damage from impacts, chemicals and weathering. Our finish options include everything from TGIC and TGIC-free polyester coatings to cermet coatings and more.

At ACT, we have more than 44 years of experience in the coating and finish industry. Our expertise also extends to the quality and service we provide to our customers. Our processes are so thorough, we have earned the ability to enter the highly specific military market. The high level of excellence we use for our military work also goes into all projects we work on. Make us your choice for a finishing company that will offer you quality coatings and excellent customer service.

Contact us to request a quote for your project's finish needs.