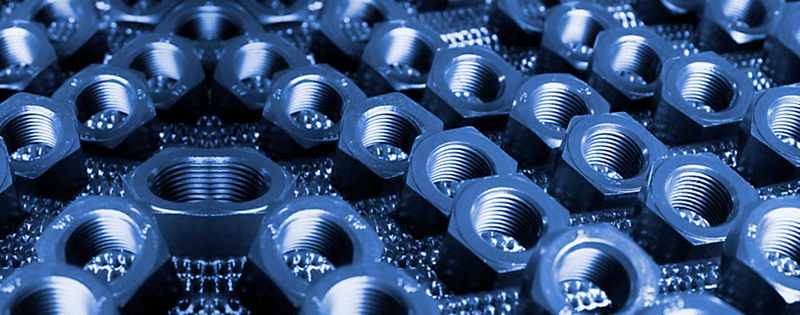

Fluoropolymer coatings are a blend of resins and fluoropolymer lubricants. PTFE, PVDF, PFA, and FEP provide low friction, chemical and corrosion resistance, non wetting, and release or non stick properties at temperatures up to 550F. ACT is a Whitford Corporation "Recommended Coater".

Xylan is a nonstick coating available with molybdenum disulfide (MoS2), polyurethane emulsion polymer (PEP), perfluoroalkyl vinyl ether copolymer (PFA) and polytetrafluoroethylene (PTFE) components. The Xylan line of coatings is extensive and available with a variety of resin binders, functional components and pigments. Xylan coating applications can be specialized to the environment to accommodate for corrosion resistance, low friction and release. With its range of applications, customers can choose a specific Xylan coating to fit their project specifications.

Dykor coatings are engineered for difficult-to-finish projects. Dykor is a powder nonstick coating for tight tolerance applications and can form a thick coat up to 30 mils. Compared to other coats, Dykor is a cost-effective solution for protecting chemical processing equipment from corrosion.

Fluoropolymers are known for their corrosion resistance and nonstick and non-wetting capabilities, in addition to their ability to withstand heat up to 550 degrees Fahrenheit.

Advanced Coating Technology can work with you to identify and the correct Xylan or Dykor coating for you application needs. They can be made for a wide variety of applications.

Problems we frequently address include:

Titanium Heat Exchanger Coated With Dykor

Dykor and Xylan are registered trademarks of Whitford Corporation

The versatility of fluoropolymers gives them several unique benefits, such as:

Fluoropolymer can withstand temperatures of up to 550 degrees Fahrenheit, making it ideal for high-heat environments. Fluoropolymer is known for its ability to operate in extreme temperature environments where competing traditional lubricants have a high chance of burning. At Advanced Coating Technology, we can provide you with the fluoropolymers you need while addressing temperature issues with solutions such as heat-seal bars and hot-melt adhesive pots and chutes.

Fluoropolymers have a high chemical resistance. Fluoropolymers are chemically inert and weather heat, electricity and friction without any fear of changes to their chemical structures. Advanced Coating Technology uses fluoropolymer's chemical resistance to provide you with equipment such as heat-seal bars, sliding/mating surfaces, hot-melt adhesive pots and components specially designed for highly corrosive conditions.

Advanced Coating Technology is experienced in applying fluoropolymer, Xylan and Dykor coatings. Advanced Coating Technology has over 44 years of experience applying coatings and are a Recommended Applicator of Xylan and Dykor products. For questions and product inquiries, contact us online or call us at 717-795-9936.